How we manage waste

Cory receives over 900,000 tonnes of non-recyclable black bag waste a year. 89 per cent comes to our riverside waste transfer stations.

Click on the numbers below to find out more about the different stages of the journey.

1. Processing recyclable materials

Cory receives, sorts and segregates dry mixed recyclables (DMR) for Western Riverside Waste Authority (WRWA) and its four London boroughs.

2. Using the River Thames

Non-recyclable waste is transported on barges using tugs via riverside transfer stations in Wandsworth, Battersea, the City of London and Tower Hamlets.

3. Processing non-recyclable waste

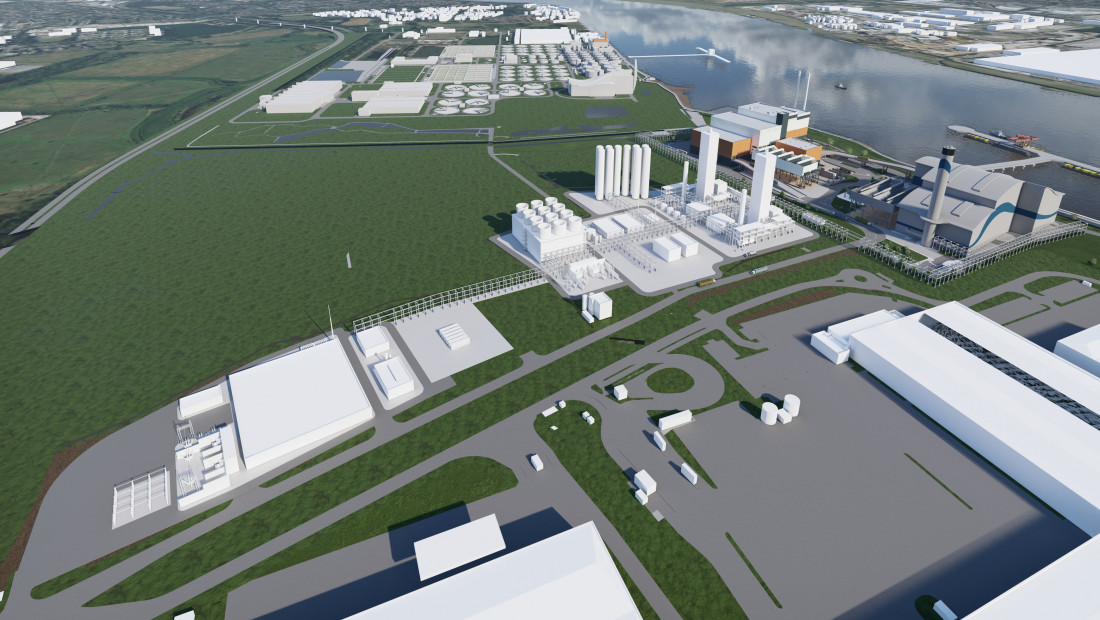

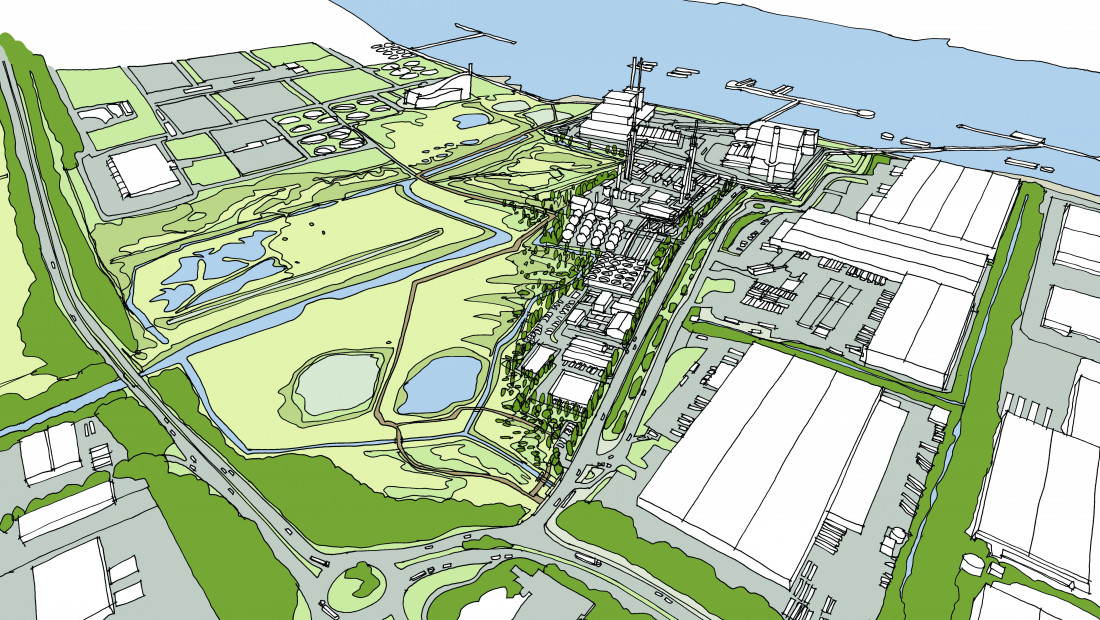

Situated in Belvedere, Cory’s Riverside facility is one of the largest operational EfW facilities in the UK and the only one with both river and road infrastructure for receiving waste.

4. Ash recycling

Metals are extracted for recycling from the ash produced by the incineration process.

5. Repairing vessels on the Thames

Cory Ship Repair Services operates two slipways at Denton Wharf in Gravesend, on the banks of the River Thames.

Having a positive impact

We work to provide a safe, clean, and sustainable way of managing recyclable and non-recyclable waste in London and the South East.

tonnes of carbon saved by not sending waste to landfill

258,000

tonnes non-recyclable ‘black bag’ waste diverted from landfill

969,000

equivalent number of homes powered by electricity generated

195,000

News and insights

Reporting centre

Annual Report 2022

Download our 2022 Annual Report to explore how we're helping make London cleaner and safer.

Sustainability Report

Download our 2022 Sustainability Report to explore how we're moving to net zero.